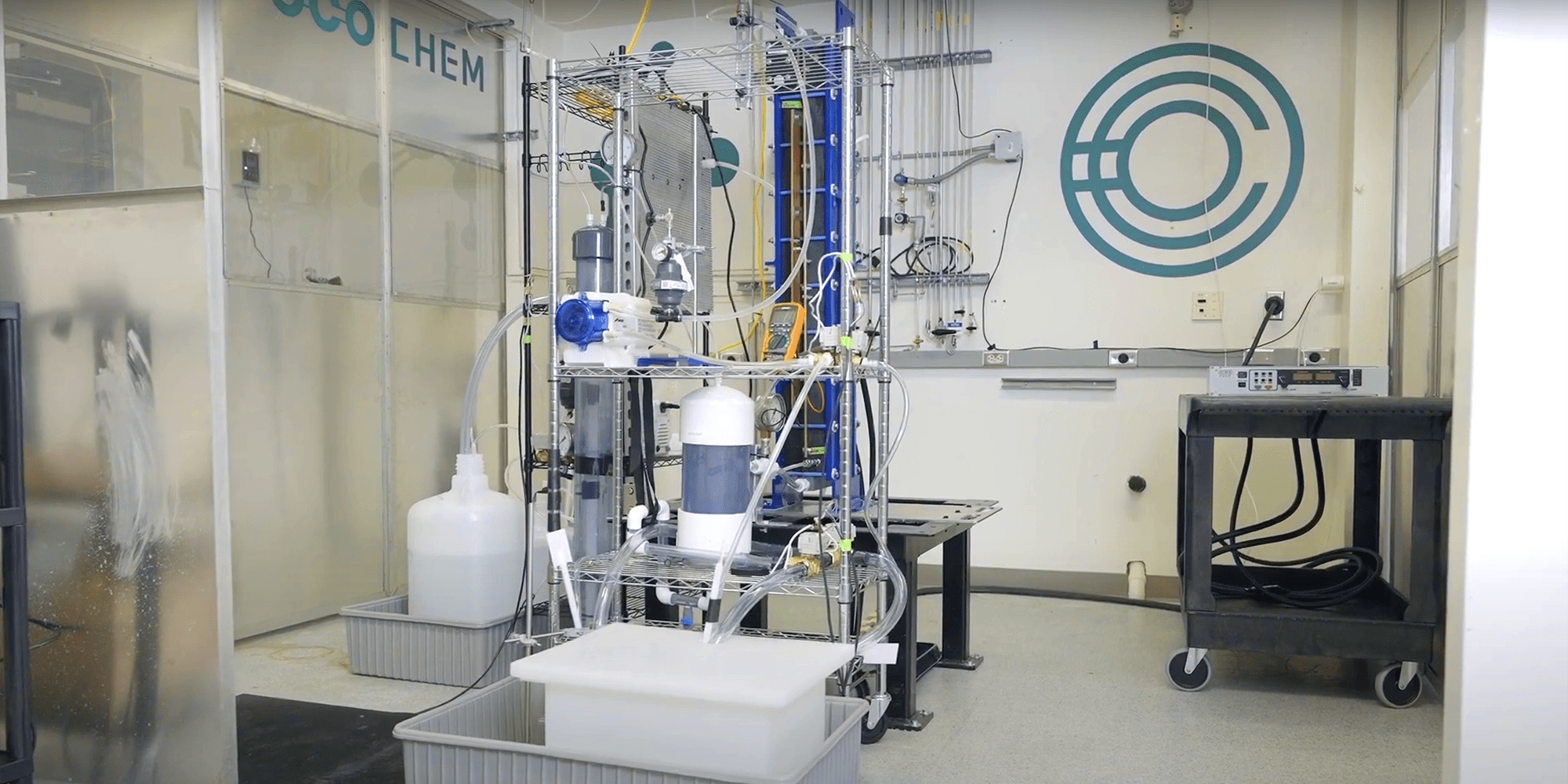

Richland, WA — [May 28, 2025) — In a landmark achievement for carbon utilization and sustainable chemical production, OCOchem today announced the successful start-up and commissioning of the world’s first pilot plant to produce hydrogen formate and potassium formate at industrial scale using only carbon dioxide and water as feedstocks. The $5.0 million facility, capable of producing 60 tons of formate per year, represents the first industrial-scale application of a CO2 Electrolysis process using commercial grade and size gas diffusion electrodes measuring 1.5m2 each in surface area.

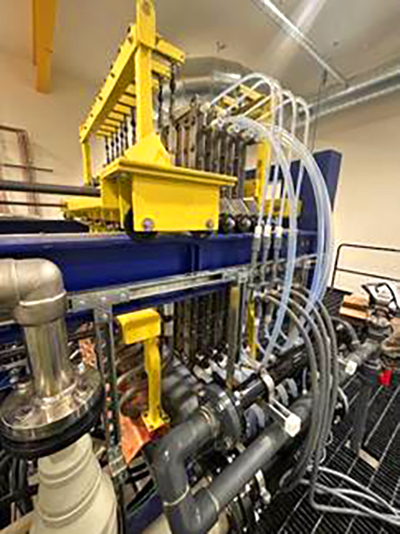

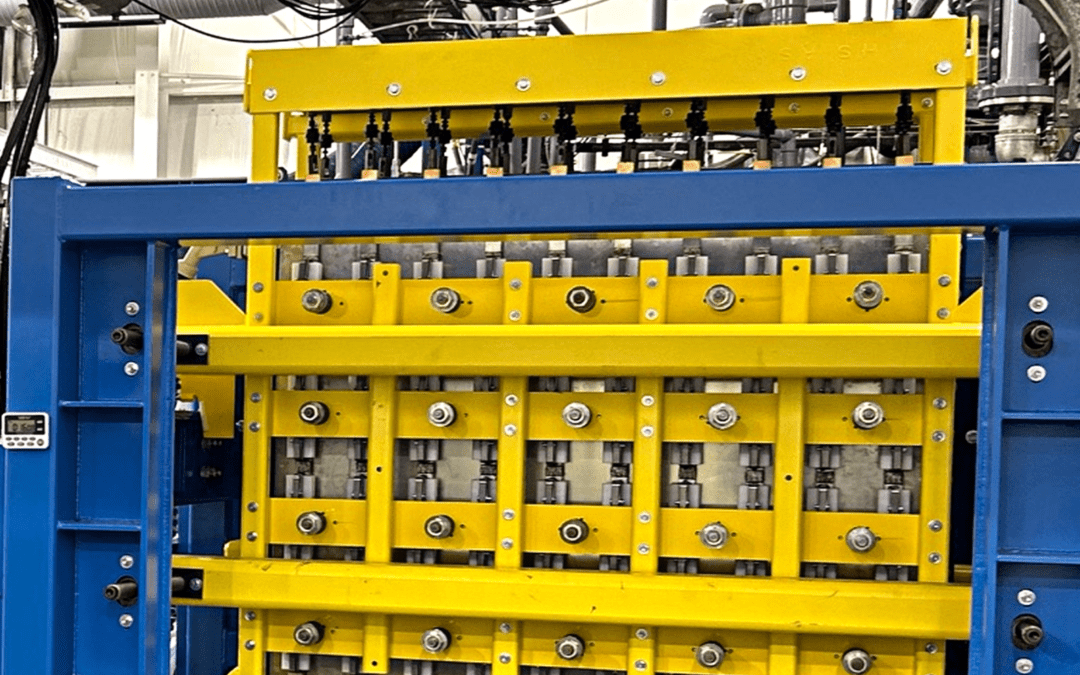

The new plant leverages a 4-cell stack of the world’s largest CO₂ electrolyzer cells —each measuring 1.5 square meters in gas diffusion electrode surface area —and operates at ambient temperature and pressure to produce formate with unprecedented energy and cost efficiency. Formate, a liquid organic molecule, is a versatile chemical used in agriculture, manufacturing, pharmaceuticals, cleaning products, metal processing and increasingly as a liquid carrier for hydrogen and carbon monoxide (syngas).

“For the last three centuries, humanity’s options to harvest useful carbon molecules have been limited to two: either grow it in the form of vegetation taking months or mine it from the earth in the form of hydrocarbons which takes millennia. We now have a 3rd way, CO2 Electrolysis, to directly and instantly synthesize organic molecules from CO2 and water. This artificial photosynthesis approach – using industrial-scale components – substantially reduces technology risk. And it allows us to accelerate our scale-out commercialization efforts at larger plant with thousands of cells,” said Todd Brix, CEO of OCOchem. “We’re proud to be the first to bring it to life at an industrial scale—unlocking a new third pathway to organic molecule manufacturing without relying on fossil fuels or biomass.”

Adds Brix: “In the world we see moving forward, the new platform molecules, the precursor molecules from which all other organic molecules are made, will increasingly start and be made from the molecules that can be made from CO2 at a lower cost than the incumbent fossil fuel-derived feedstocks. That means a C1 molecule, and that means a 2-electron molecule. Of all the carbon molecules that can be made from CO2, only hydrogen formate (also known as formic acid) can meet this standard with today’s energy cost.”

A New Industrial Pathway

Today, most organic chemicals are derived from fossil carbon, which generate massive CO2 emissions and air pollution when consumed, or grown carbon, which consumes scarce land and water resources and competes with food and feed production raising prices. OCOchem’s process inverts that model by directly consuming and converting CO₂ and water into value-added molecules, powered by clean electricity and advanced, patented CO₂ electrolysis process and material technologies.

According to independent third-party analyst firm, EcoEngineers, each ton of formate produced by OCOchem’s system removes and avoids a combined 7.2 tons of CO₂ emissions by both consuming captured carbon dioxide and displacing fossil fuels used as feedstocks and energy sources to make chemicals. With just four industrial cells operating in the pilot, the design can easily scale by “numbering up” the cells, lowering capital costs and enabling rapid expansion.

Moreover, most chemical plants today are assembled on-site in a “stick-built” manner. By contrast, OCOchem’s pilot plant was fully fabricated off-site, delivered, rolled into place, and commissioned in just six weeks—an unusually rapid timeline that dramatically reduces chemical production facilities’ build and start-up costs. This modular molecule factory approach enables faster deployment and opens the door to a new distributed production model, where organic molecule factories can be mass-produced in factories and can be rapidly deployed anywhere CO₂ is available.

“The implications of this are enormous,” said Bob Weber, a longtime expert in carbon-to-chemical technologies and former Pacific Northwest National Laboratory researcher. “OCOchem has demonstrated that electrochemical CO₂ utilization can function at meaningful scale, and at ever-decreasing cost, setting a new standard for clean chemical production.”

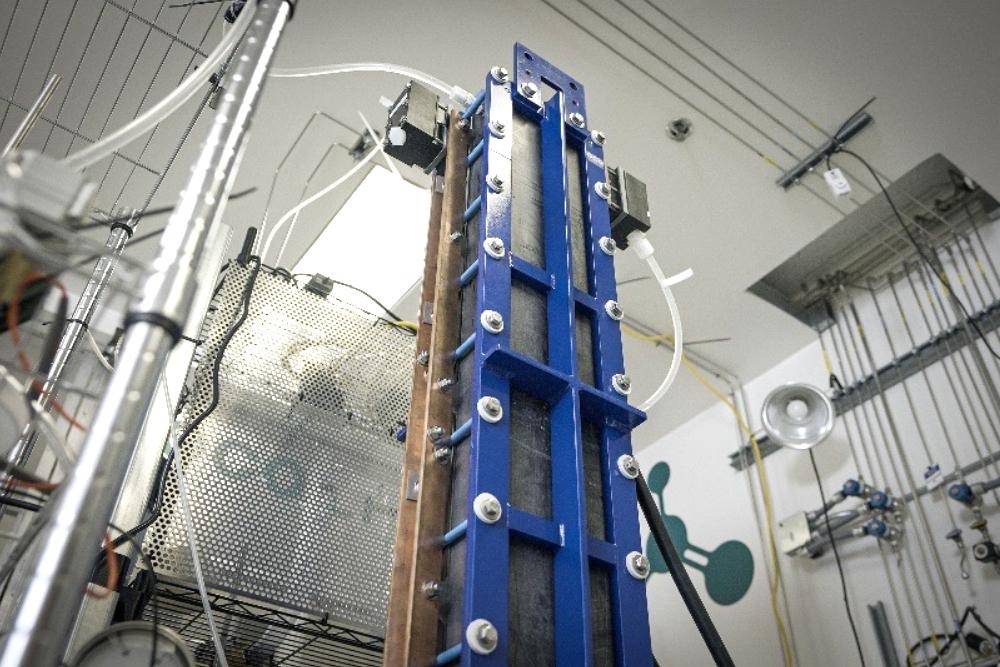

OCOchem Carbon FluX Electrolyzer pilot plant for formate production (Anolyte Skid (L), Electrolyzer Carriage (M), Catholyte Skid (R)).

Technology Built for Scale

OCOchem’s breakthrough integrates several proprietary innovations, including:

- Patented CO₂ gas diffusion electrodes developed in-house, achieving 100x greater CO₂ conversion than traditional aqueous or solubility-limited systems

- A 2-in-1 electrolyzer design that both electrolyzer water to make hydrogen (at the anode) and then chemically bonds that hydrogen, moments later, to CO2 (at the cathode)

- Electrolyzer cells 20 times larger than those used in current fuel cell and hydrogen electrolyzer technologies

- Modular factory-assembled skid-mounted processing units, fabricated off-site and installed in under six weeks

- Operation at ambient temperature and pressure, significantly lowering energy, piping, and equipment costs while also enabling load-following operation.

- High-concentration formate production exceeding 35%, enabling more efficient downstream processing and lower separations cost.

OCOchem’s modular, rapidly deployable molecule plants offer a transformative solution for both companies with excess CO₂ and renewable energy developers seeking new value streams. By enabling local, distributed production of carbon-based molecules, these systems enhance supply chain resiliency and create high-value outputs directly from waste CO₂. Ideal deployment sites include bio-refineries, renewable natural gas facilities, and CO₂ capture locations—anywhere CO₂ is available and underutilized.

Because the technology operates at ambient temperature and pressure, it is inherently load-following and ideal for co-location with renewable, but often intermittent, power sources. This opens new opportunities for solar, wind, hydro, geothermal, or even off-grid nuclear project developers to convert stranded or underutilized power directly into valuable organic molecules, without the delay or cost of grid interconnects or battery storage. Together, these capabilities unlock a scalable model for sustainable, distributed organic molecule production where CO₂ and renewable electrons are found.

This successful pilot lays the foundation for a broad range of future products derived from CO₂ and formate, including clean fuels, agrochemicals, industrial solvents, and liquid hydrogen carriers. With low-cost feedstocks, modular scalability, and climate-positive economics, OCOchem is poised to drive a transformative shift in how the world produces and distributes carbon-based molecules.

About OCOchem

OCOchem is a leading clean chemistry innovator that has pioneered technologies that convert carbon dioxide and water into renewable molecules and materials. Focusing on decarbonizing global supply chains and building a more sustainable industrial future, OCOchem is pursuing this goal by utilizing a novel approach that integrates proprietary electrochemical systems with cost-effective and easily scalable production methods.

Media Contact:

Steven Gottlieb

(206) 427-9591

steven@gottliebgroup.consulting