New chemical technology to be used to protect military base roads, vehicles, and the environment; could save U.S. taxpayers hundreds of billions of dollars annually

(Richland, WA – Sept. 19, 2022) – Clean fuel and chemical innovator OCOchem has been awarded an extension of its $1.1 million contract to create a chemical process to manufacture a lower-cost, non-corrosive, chlorine-free deicer to protect U.S. Army and other military equipment from the damage caused by rock or road salt.

Once produced to scale – and if adopted broadly for military and civilian use – the new chemical would replace the use of chloride-based deicing salts and save U.S. state and local governments more than $100 billion in annual corrosion-related road, bridge and equipment maintenance costs and help protect the environment and water supplies.

The U.S. military, as well as state and local governments in cold-weather environments, use chemical deicers to melt dangerous ice on roads, walkways, and runways. U.S. military facilities throughout the world rely on deicers to keep their bases operational and mission ready 24/7. However, the most common de-icing chemicals used today, due to their historically lower costs, are chloride-based salts.

“These salts have negative effects on the environment and surrounding infrastructure after they are applied, dissolved, and dispersed,” said Todd Brix, co-founder and chief executive of Richland-based OCOchem.

Such negative effects include corrosion of vehicles, equipment and metal components (like rebar and joints) used in bridges and transportation infrastructure, soil and drinking water contamination from chemical runoff, and vegetation damage. According to a report issued by the General Accounting Office in 2016, corrosion cost the U.S. Department of Defense nearly $21 billion in FY2011. Beyond the U.S. Army and Department of Defense, the annual estimated economic cost of the negative effects of chloride-based de-icing chemicals exceeds $100 billion in the civilian economy of the United States. It is also the primary cause of the $561 billion the United States spends annually on corrosion, according to NACE International, accelerating the deterioration of infrastructure necessary to move people and goods all over the United States.

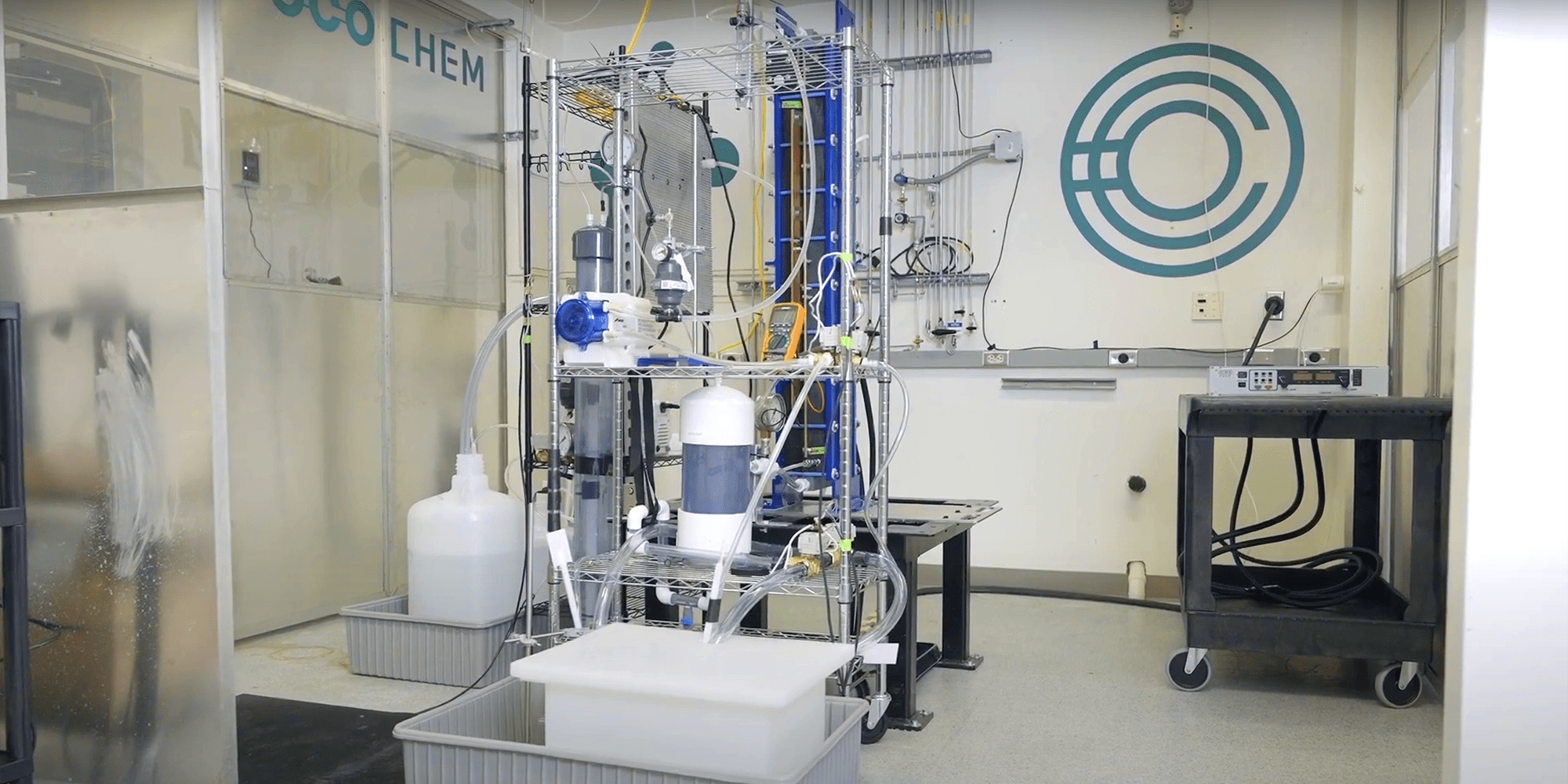

OCOchem has developed a cost-effective process to create non-corrosive potassium formate deicer using inexpensive, and recycled carbon dioxide (CO2) emissions, water, potassium sulfate, and clean electricity. Although other potassium formate deicers exist and are commonly used in airports and for home use, they are made from fossil fuels. OCOchem’s process greatly reduces the price by using abundant recycled CO2 to make it affordable.

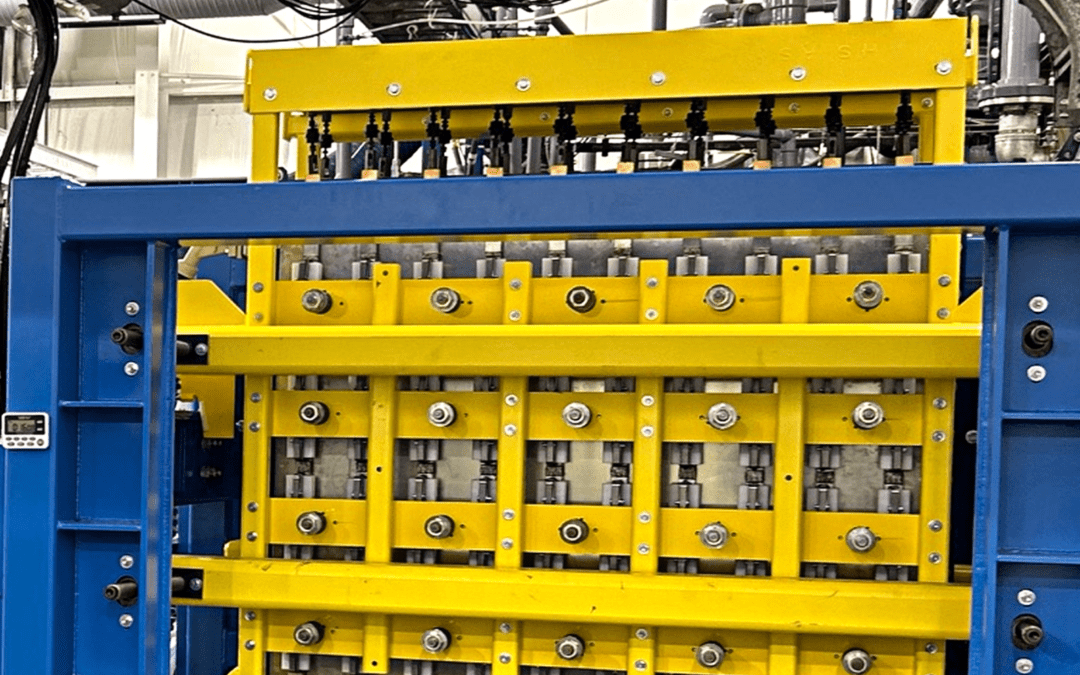

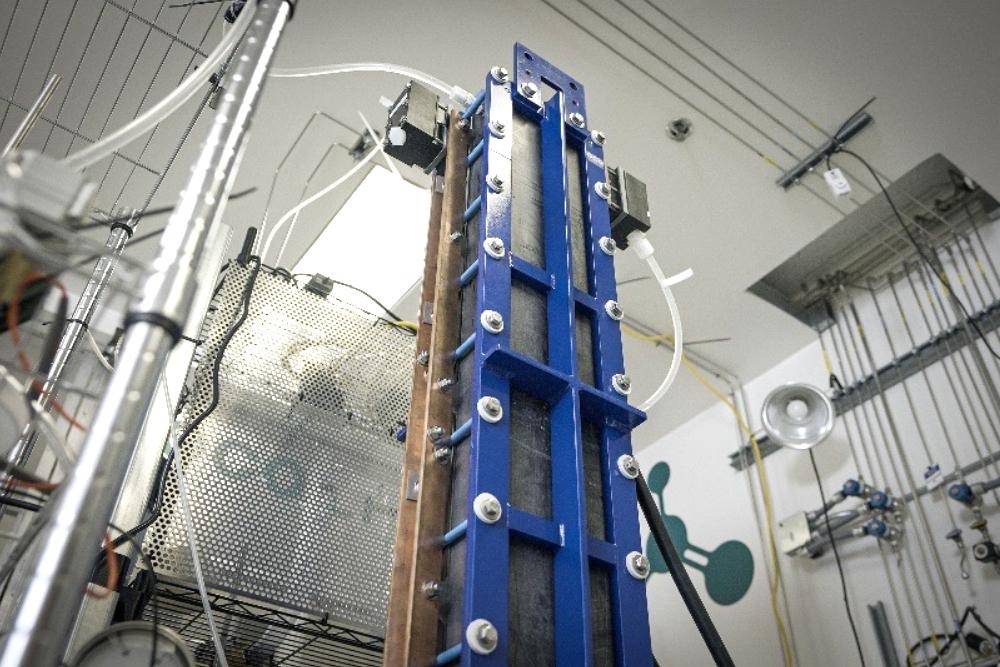

With the U.S. Army grant, OCOchem in August built the first large scale prototype-scale mobile Carbon Flux Electrolyzer™ that produces potassium formate in a ready-to-use liquid brine formulation for use as a corrosion-free deicer. The formate electrolyzer can fit on the back of a military vehicle, making it directly accessible to bases throughout the world.

The prototype – a wonder of electrical, chemical and mechanical engineering invented, created and demonstrated at OCOchem’s Richland headquarters — is the world’s first formate electrolyzer of this size. It is 18 times larger than the initial prototype developed by Brix and his team.

The new deicer – if widely adopted by the military and civilian users – has the potential to not only save U.S. taxpayers more than $100 billion per year through reduced corrosion, maintenance, and replacement costs currently caused by using chloride-based deicers, but to also:

- Enhance supply chain resilience and reduce logistics costs and risks by allowing the new de-icing chemicals to be made on-site at U.S. military bases.

- Lower potassium formate costs by more than 30%, enabling expanded use.

- Create a shorter and more resilient U.S.-only supply chain that does not rely on chemicals imported from abroad. Potassium formate would be produced on-site using OCOchem’s Carbon Flux Electrolyzer™ and U.S.-sourced recycled CO2, water, and potassium sulfate.

- Cut environmental and water supply contamination and salination by reducing chloride salt-based deicer runoff.

- Reduce CO2 emissions by capturing and recycling CO2 from on-base emission sources, such as diesel generators, natural gas turbines, and heaters.

- Reduce overall CO2 emissions by more than 100 million tons per year in the United States (2% of annual U.S. greenhouse gas emissions) if traditional rock salt deicers are entirely replaced with this approach.

“The potential impact of this novel lower-cost carbon-neutral deicing manufacturing process delivers a triple benefit to national defense readiness, civilian customers, and the environment,” Brix said. “We are excited to continue our efforts to further scale our formate electrolyzer technology to a commercial-ready system for the U.S. Army so that the new low-cost corrosion-free deicer can be used at U.S. military bases throughout the world and be deployed in the civilian sector to more affordably enhance safe travel and to protect and extend the longevity of our natural and built environment.”

The project depicted is supported by the U.S. Army Research Office. The information does not necessarily reflect the position or the policy of the U.S. Government, and no official endorsement should be inferred.